Welcome to the official website of Yaweier (Beijing) Technology Co., Ltd.!

Raw Material Source:

Coconut Shell Carbon: Derived from coconut shells, which are rich in cellulose, lignin, and other organic components. This makes it a natural biomass material. In areas with abundant coconut production, such as Southeast Asia and South America, large quantities of coconut shells are collected to produce coconut shell carbon.

Coal-Based Carbon: Made from coal, a fossil fuel formed from ancient plants over long geological periods. Coal can be classified into types such as lignite, bituminous coal, and anthracite based on the degree of coalification. All these types can be used to prepare coal-based carbon. Anthracite, due to its high fixed carbon content and low impurity levels, is considered a premium raw material for producing coal-based carbon.

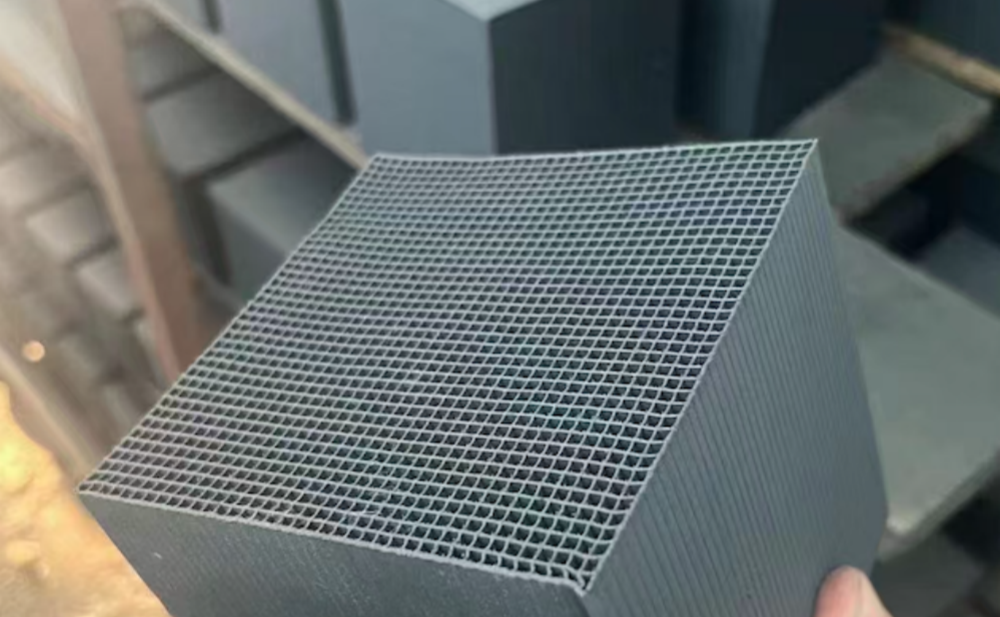

Appearance and Structure:

Coconut Shell Carbon: Typically appears granular with relatively uniform particles and a smooth surface. It features a well-developed microporous structure with a concentrated pore size distribution, generally around 1-2 nanometers in diameter. The specific surface area is large, usually reaching 1000-1200 square meters per gram, which gives coconut shell carbon strong adsorption capabilities.

Coal-Based Carbon: Comes in various forms, including granular, columnar, and powdered shapes. Its pore structure is relatively complex, with a wide pore size distribution that includes micropores, mesopores, and macropores. The specific surface area generally ranges from 800-1000 square meters per gram, and its adsorption properties vary based on raw material and production process.

Production Process:

Coconut Shell Carbon: Typically produced using physical or chemical methods. The physical method involves carbonizing coconut shells at high temperatures followed by activation with gases such as steam or carbon dioxide to develop a rich pore structure. The chemical method involves mixing coconut shells with chemical agents under specific conditions for carbonization and activation, commonly using agents like zinc chloride and phosphoric acid.

Coal-Based Carbon: The production process involves carbonization and activation. Initially, coal is carbonized in an oxygen-free environment, allowing volatile components to escape and forming semi-coke. This semi-coke is then activated with agents such as steam or carbon dioxide to increase porosity and specific surface area, thereby enhancing adsorption performance.

Performance Characteristics:

Coconut Shell Carbon: Exhibits high adsorption performance, especially effective for small molecules. It effectively removes residual chlorine and organic substances in water treatment and strongly adsorbs harmful gases like formaldehyde and benzene in air purification. Additionally, coconut shell carbon is chemically stable, mechanically strong, and has a long service life.

Coal-Based Carbon: Also offers strong adsorption performance, particularly advantageous for large molecular organics and heavy metal ions. It is relatively cost-effective, making it widely used in fields with strict cost requirements, such as industrial wastewater treatment, and flue gas desulfurization and denitrification.

SEO Keywords: Coconut Shell Carbon, Coal-Based Carbon, Biomass Material, Adsorption Performance, Water Treatment, Air Purification, Chemical Stability,

Cost-Effective, Microporous Structure.

Yaweier (Beijing) Technology Co., Ltd. XML