Technical support for water purification equipment

At a time when water quality requirements are strict, our water purification equipment factory provides advanced, efficient and reliable water purification solutions.

The following introduces key technologies and support content.

Core technology

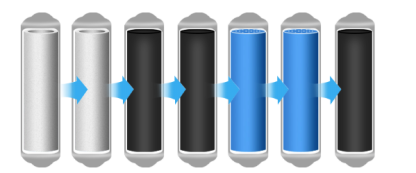

Filter element technology

Granular activated carbon filter element: rich internal pores, can absorb physical, chemical and biological organic small molecule impurities in water. Fine-grained

activated carbon is used to increase the contact area, remove residual chlorine, odor, some heavy metal ions, etc., and provide high-quality water for subsequent

processes.

Compressed activated carbon filter element: compressed and formed by a special process, with a larger specific surface area. It can deeply adsorb colloids,

organic matter, chromaticity, etc., and filter tiny impurities for the second time to improve water quality.

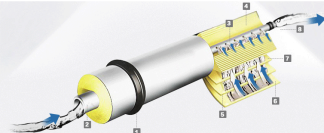

RO reverse osmosis membrane filter element: It is the core component of the equipment and adopts reverse osmosis technology. The membrane pore size is

extremely small, only allowing water molecules to pass through, and can separate ions, heavy metals, bacteria, viruses, etc. The filtration accuracy reaches

0.0001 microns to ensure that the water quality meets the standards.

Reverse osmosis membrane selection

We use reverse osmosis membranes that have been certified by international authorities. They have high desalination rate, good chemical stability, long service

life, and provide high-quality purified water in a long-term and stable manner.

Suspended matter pretreatment technology

Filter element pretreatment: In small flow scenarios such as households, use PP cotton filter elements, stainless steel filter screens, etc. to intercept ≥50μm

particle impurities, such as sediment and rust, to protect subsequent equipment. PP cotton filter elements need to be replaced regularly, and stainless steel

filter screens can be backwashed.

Ion exchanger pretreatment: In small-scale water purification projects, ion exchangers remove suspended matter and some hardness ions through ion exchange,

reduce water hardness, and reduce the burden of subsequent treatment.

Equipment maintenance

Filter element cleaning and replacement

Granular and compressed activated carbon filter elements: It is recommended to replace them every 6-12 months. When the water quality deteriorates, the taste

is peculiar, and the water output decreases, it is necessary to check and replace them in time. Some washable filter elements can be backwashed regularly, but

frequent operation is not recommended.

RO reverse osmosis membrane filter element: The service life is 2-3 years, which is affected by the quality of raw water and water consumption. When the operating

pressure increases and the water output decreases, it needs to be cleaned or replaced. Use professional cleaning agents for cleaning and follow the process.

Overall equipment maintenance

Prevent filter leakage: Ensure that the filter outlet device is installed correctly and well sealed to prevent filter leakage. Check the quality of activated carbon regularly

to avoid powder loss.

Stable water supply system: When large-scale pure water equipment uses tap water as the water source, an independent water supply system is set up to ensure

stable water supply and reduce the start-up and shutdown impact of the RO system. The RO device directly takes water and high and low pressure protection

facilities must be installed.

Reagent compatibility management: When purifying water, choose reagents reasonably, considering the compatibility between reagents and membrane materials.

For example, cationic coagulants and negatively charged scale inhibitors should avoid reaction to prevent colloid deposition on the membrane surface. Test

thoroughly before adding reagents and operate according to regulations.

FAQ

Water quality does not meet the standard

Reason: The filter element has been used for a long time, the raw water quality has deteriorated, the equipment has leaked, and the reagent has problems.

Solution: Replace the filter element, check the raw water, repair the leak, and calibrate the reagent.

Reduced water output

Reason: Filter element blockage, water pump failure, pipe blockage, RO membrane contamination and scaling.

Solution: Clean or replace filter element, check water pump, flush pipe, clean or replace RO membrane.

Noisy equipment operation

Reason: Water pump bearing problem, motor failure, unstable pipe fixation, unstable equipment foundation.

Solution: Lubricate or replace bearings, check motor, fix pipes, and strengthen equipment foundation.

We have a professional technical team to provide technical consultation, installation and commissioning, repair and maintenance services. If you encounter any

problems, contact the customer service team to ensure your water safety and stable equipment operation.